The abap programming report in sap is a tool you can use to analyze and act on the recommendations from the last MRP/MPS run. Depending on user-defined filters, the report collectively displays all of the materials, exception messages, on-hand quantities, and other data used in the run. A production planner or buyer would use this report to assess and prioritize procurement action or manufacturing runs.

This sap report does rely on the underlying settings for MRP. There is one key piece of master data required for reporting: the MRP controller on the MRP 1 view of the material master. Since the report reflects data current as of the last MRP run, its use should be coordinated with the timing and frequency of the run.

From the summary, you can review the individual MRP list for a given material. Then, you can display additional material data, detailed review, or immediate conversion of MRP recommendations to procurement/manufacturing orders.

From the report, an individual MRP list may be selected and displayed by doubleclicking on the line. Another option is to select several lines and sequentially page through these lines using Edit → MRP list sequence. From the Edit menu, it is possible to search and sort on exceptions. From the Goto menu you can branch to the current stock/requirements list, review the exception message codes and their grouping logic, and invoke interactive MRP planning.

Interactive MRP planning can update the MRP database with new results, if saved. Once the individual MRP list is displayed, numerous options are provided for a detailed display of the underlying master data and the conversion action on planned orders and purchase requisitions. The capabilities are essentially the same as the stock/requirements list, and as such have the potential for updates to the database.

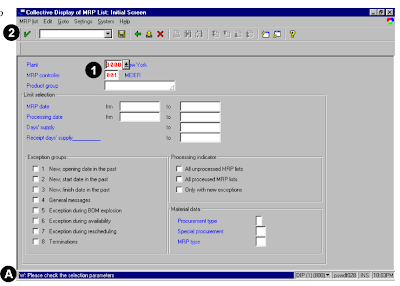

To access the first screen for this report, choose Logistics → Production → MRP → Evaluations → MRP list – coll.display.

1. You must enter the Plant and MRP controller.

All other fields are optional filters that further limit the selection.

2. Choose Enter. A The message in the status bar is a precaution to avoid wasted runtime on incomplete selections.

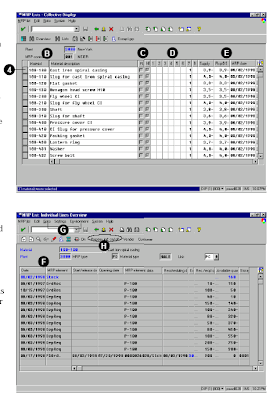

The collective display reflects the following:

The collective display reflects the following:B Material number and description

C Processing and new exception indicators

D Number of exception messages and exception group for material

E Additional information about the material

4. Double-click on a line to display the individual MRP list.

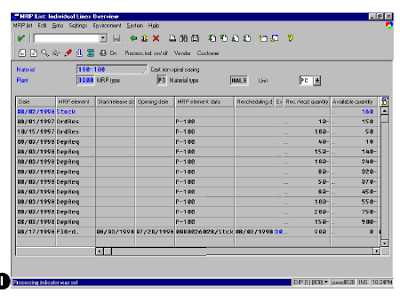

F The individual MRP list reflects the source of supply and demand by date.

G For further detail, choose Goto or Environment menus.

H The processing indicator may be manually set to flag the item. This indicator can also be set as a filter criteria on the first screen of this report.

The message in the status bar shows that the indicator was set.

The message in the status bar shows that the indicator was set.