This sap programming report with sample code using abap programming language explains you how to use alv block list to append the report.

REPORT ZALVBLOCK .

TYPE-POOLS : SLIS.

TABLES : AFKO,AFPO.

TYPES : BEGIN OF SAFPO ,

AUFNR LIKE AFPO-AUFNR,

POSNR LIKE AFPO-POSNR,

PLNUM LIKE AFPO-PLNUM,

STRMP LIKE AFPO-STRMP,

MATNR LIKE AFPO-MATNR,

PSMNG LIKE AFPO-PSMNG,

MEINS LIKE AFPO-MEINS,

END OF SAFPO.

TYPES : BEGIN OF SAFKO,

AUFNR LIKE AFKO-AUFNR,

END OF SAFKO.

DATA : IAFKO TYPE TABLE OF SAFKO WITH HEADER LINE,

IAFPO TYPE TABLE OF SAFPO WITH HEADER LINE.

DATA : IFIELDCAT1 TYPE SLIS_T_FIELDCAT_ALV,

WFIELDCAT1 TYPE SLIS_FIELDCAT_ALV,

ILAYOUT1 TYPE SLIS_LAYOUT_ALV,

IEVENT1 TYPE SLIS_T_EVENT,

WEVENT1 TYPE SLIS_ALV_EVENT,

IKEYINFO1 TYPE SLIS_KEYINFO_ALV.

DATA : IFIELDCAT2 TYPE SLIS_T_FIELDCAT_ALV,

WFIELDCAT2 TYPE SLIS_FIELDCAT_ALV,

ILAYOUT2 TYPE SLIS_LAYOUT_ALV,

IEVENT2 TYPE SLIS_T_EVENT,

WEVENT2 TYPE SLIS_ALV_EVENT.

SELECTION-SCREEN BEGIN OF BLOCK B1 WITH FRAME TITLE TEXT-001.

SELECT-OPTIONS : S_AUFNR FOR AFKO-AUFNR,

S_GLTRP FOR AFKO-GLTRP.

SELECTION-SCREEN END OF BLOCK B1.

START-OF-SELECTION.

CALL FUNCTION 'REUSE_ALV_BLOCK_LIST_INIT'

EXPORTING

I_CALLBACK_PROGRAM = SY-REPID.

- I_CALLBACK_PF_STATUS_SET = ' '

- I_CALLBACK_USER_COMMAND = ' '

- IT_EXCLUDING =

.

PERFORM GET_DATA.

PERFORM BUILD_FIELDCAT.

PERFORM BUILD_LAYOUT.

PERFORM BUILD_EVENT.

PERFORM BUILD_KEYINFO.

PERFORM BUILD_FIELDCAT2.

PERFORM BUILD_LAYOUT2.

PERFORM BUILD_EVENT2.

PERFORM DISPLAY_BLOCK1.

PERFORM DISPLAY_BLOCK2.

CALL FUNCTION 'REUSE_ALV_BLOCK_LIST_DISPLAY'

- EXPORTING

- I_INTERFACE_CHECK = ' '

- IS_PRINT =

- I_SCREEN_START_COLUMN = 0

- I_SCREEN_START_LINE = 0

- I_SCREEN_END_COLUMN = 0

- I_SCREEN_END_LINE = 0

- IMPORTING

- E_EXIT_CAUSED_BY_CALLER =

- ES_EXIT_CAUSED_BY_USER =

EXCEPTIONS

PROGRAM_ERROR = 1

OTHERS = 2

.

IF SY-SUBRC 0.

- MESSAGE ID SY-MSGID TYPE SY-MSGTY NUMBER SY-MSGNO

- WITH SY-MSGV1 SY-MSGV2 SY-MSGV3 SY-MSGV4.

ENDIF.

&---------------------------------------------------------------------

*& Form GET_DATA

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM GET_DATA .

SELECT AUFNR FROM AFKO INTO CORRESPONDING FIELDS OF TABLE IAFKO

WHERE AUFNR IN S_AUFNR AND GLTRP IN S_GLTRP.

SELECT AUFNR POSNR PLNUM STRMP MATNR PSMNG MEINS FROM AFPO INTO CORRESPONDING FIELDS OF TABLE

IAFPO WHERE AUFNR IN S_AUFNR.

ENDFORM. " GET_DATA

&---------------------------------------------------------------------

*& Form BUILD_FIELDCAT

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_FIELDCAT .

REFRESH : IFIELDCAT1.

*WFIELDCAT1-FIELDNAME = 'AUFNR'.

*WFIELDCAT1-COL_POS = '1'.

*WFIELDCAT1-SELTEXT_L = 'Order No'.

*APPEND WFIELDCAT1 TO IFIELDCAT1.

*CLEAR WFIELDCAT1.

WFIELDCAT1-FIELDNAME = 'GLTRP'.

WFIELDCAT1-COL_POS = '1'.

WFIELDCAT1-SELTEXT_L = 'Basic Finish Time'.

APPEND WFIELDCAT1 TO IFIELDCAT1.

CLEAR WFIELDCAT1.

WFIELDCAT1-FIELDNAME = 'GSTRP'.

WFIELDCAT1-COL_POS = '2'.

WFIELDCAT1-SELTEXT_L = 'Basic Start Time'.

APPEND WFIELDCAT1 TO IFIELDCAT1.

CLEAR WFIELDCAT1.

WFIELDCAT1-FIELDNAME = 'GAMNG'.

WFIELDCAT1-COL_POS = '3'.

WFIELDCAT1-SELTEXT_L = 'Total Order Qty'.

APPEND WFIELDCAT1 TO IFIELDCAT1.

CLEAR WFIELDCAT1.

WFIELDCAT1-FIELDNAME = 'GMEIN'.

WFIELDCAT1-COL_POS = '4'.

WFIELDCAT1-SELTEXT_L = 'UOM'.

APPEND WFIELDCAT1 TO IFIELDCAT1.

CLEAR WFIELDCAT1.

ENDFORM. " BUILD_FIELDCAT

&---------------------------------------------------------------------

*& Form BUILD_LAYOUT

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_LAYOUT .

ILAYOUT1-COLWIDTH_OPTIMIZE = 'X'.

ILAYOUT1-ZEBRA = 'X'.

ENDFORM. " BUILD_LAYOUT

&---------------------------------------------------------------------

*& Form BUILD_EVENT

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_EVENT .

WEVENT1-FORM = 'TOPOFLIST1'.

WEVENT1-NAME = SLIS_EV_TOP_OF_LIST.

APPEND WEVENT1 TO IEVENT1.

ENDFORM. " BUILD_EVENT

&---------------------------------------------------------------------

*& Form DISPLAY_BLOCK1

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM DISPLAY_BLOCK1 .

*CALL FUNCTION 'REUSE_ALV_BLOCK_LIST_HS_APPEND'

- EXPORTING

- IS_LAYOUT = ILAYOUT1

- IT_FIELDCAT = IFIELDCAT2

- IS_KEYINFO = IKEYINFO1

- I_HEADER_TABNAME = 'IAFKO'

- I_ITEM_TABNAME = 'IAFPO'

- IT_EVENTS = IEVENT1

- TABLES

- T_OUTTAB_HEADER = IAFKO

- T_OUTTAB_ITEM = IAFPO

- EXCEPTIONS

- PROGRAM_ERROR = 1

- MAXIMUM_OF_APPENDS_REACHED = 2

- OTHERS = 3

- .

*IF SY-SUBRC 0.

-

- MESSAGE ID SY-MSGID TYPE SY-MSGTY NUMBER SY-MSGNO

- WITH SY-MSGV1 SY-MSGV2 SY-MSGV3 SY-MSGV4.

*ENDIF.

*

CALL FUNCTION 'REUSE_ALV_BLOCK_LIST_APPEND'

EXPORTING

IS_LAYOUT = ILAYOUT1

IT_FIELDCAT = IFIELDCAT1

I_TABNAME = 'IAFKO'

IT_EVENTS = IEVENT1

TABLES

T_OUTTAB = IAFKO

EXCEPTIONS

PROGRAM_ERROR = 1

MAXIMUM_OF_APPENDS_REACHED = 2

OTHERS = 3

.

IF SY-SUBRC 0.

- MESSAGE ID SY-MSGID TYPE SY-MSGTY NUMBER SY-MSGNO

- WITH SY-MSGV1 SY-MSGV2 SY-MSGV3 SY-MSGV4.

ENDIF.

ENDFORM. " DISPLAY_BLOCK1

FORM TOPOFLIST1.

WRITE :/10 'TABLE AFKO CONTENTS'.

WRITE :/(30) SY-ULINE.

ENDFORM.

&---------------------------------------------------------------------

*& Form BUILD_FIELDCAT2

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_FIELDCAT2 .

REFRESH : IFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'AUFNR'.

WFIELDCAT2-COL_POS = '1'.

WFIELDCAT2-SELTEXT_L = 'Order No'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'POSNR'.

WFIELDCAT2-COL_POS = '2'.

WFIELDCAT2-SELTEXT_L = 'Order Item No'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'PLNUM'.

WFIELDCAT2-COL_POS = '3'.

WFIELDCAT2-SELTEXT_L = 'Planned Order No'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'STRMP'.

WFIELDCAT2-COL_POS = '4'.

WFIELDCAT2-SELTEXT_L = 'Strt Dt Plnd ordr No'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'MATNR'.

WFIELDCAT2-COL_POS = '5'.

WFIELDCAT2-SELTEXT_L = 'Material No'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'PSMNG'.

WFIELDCAT2-COL_POS = '6'.

WFIELDCAT2-SELTEXT_L = 'Pland Ordr Qty'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

WFIELDCAT2-FIELDNAME = 'MEINS'.

WFIELDCAT2-COL_POS = '7'.

WFIELDCAT2-SELTEXT_L = 'UOM'.

APPEND WFIELDCAT2 TO IFIELDCAT2.

CLEAR WFIELDCAT2.

ENDFORM. " BUILD_FIELDCAT2

&---------------------------------------------------------------------

*& Form BUILD_LAYOUT2

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_LAYOUT2 .

ILAYOUT2-COLWIDTH_OPTIMIZE = 'X'.

ILAYOUT2-ZEBRA = 'X'.

ENDFORM. " BUILD_LAYOUT2

&---------------------------------------------------------------------

*& Form BUILD_EVENT2

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_EVENT2 .

WEVENT2-FORM = 'TOPOFLIST2'.

WEVENT2-NAME = SLIS_EV_TOP_OF_LIST.

APPEND WEVENT2 TO IEVENT2.

CLEAR WEVENT2.

ENDFORM. " BUILD_EVENT2

&---------------------------------------------------------------------

*& Form DISPLAY_BLOCK2

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM DISPLAY_BLOCK2 .

CALL FUNCTION 'REUSE_ALV_BLOCK_LIST_APPEND'

EXPORTING

IS_LAYOUT = ILAYOUT2

IT_FIELDCAT = IFIELDCAT2

I_TABNAME = 'IAFPO'

IT_EVENTS = IEVENT2

TABLES

T_OUTTAB = IAFPO

- EXCEPTIONS

- PROGRAM_ERROR = 1

- MAXIMUM_OF_APPENDS_REACHED = 2

- OTHERS = 3

.

IF SY-SUBRC <> 0.

- MESSAGE ID SY-MSGID TYPE SY-MSGTY NUMBER SY-MSGNO

- WITH SY-MSGV1 SY-MSGV2 SY-MSGV3 SY-MSGV4.

ENDIF.

ENDFORM. " DISPLAY_BLOCK2

FORM TOPOFLIST2.

WRITE : /10 'TABLE AFPO CONTENTS'.

WRITE :/(35) SY-ULINE.

ENDFORM.

&---------------------------------------------------------------------

*& Form BUILD_KEYINFO

&---------------------------------------------------------------------

----------------------------------------------------------------------

- --> p1 text

- <-- li="" p2="" text="">

----------------------------------------------------------------------

FORM BUILD_KEYINFO .

IKEYINFO1-HEADER01 = 'AUFNR'.

IKEYINFO1-ITEM01 = 'AUFNR'.

ENDFORM. " BUILD_KEYINFO

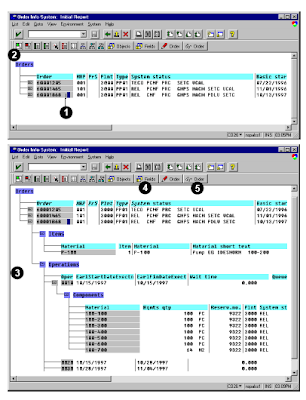

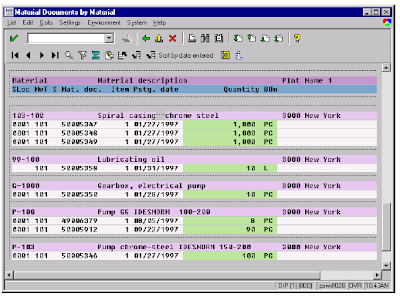

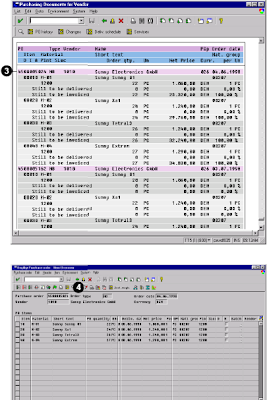

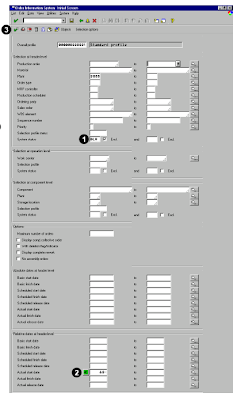

This screen shows the Object Overview. The orders are listed along with the various status codes from the order. Click the node to expand the line entry.

This screen shows the Object Overview. The orders are listed along with the various status codes from the order. Click the node to expand the line entry. 1. Enter DLV in System status and then, select Excl. (exclude). This selection assures that the report will ignore orders that are “technically completed.”

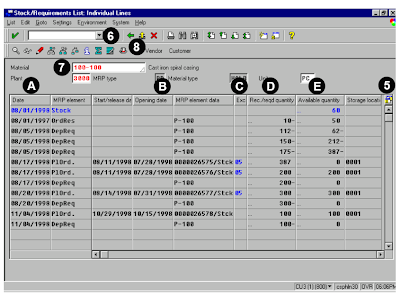

1. Enter DLV in System status and then, select Excl. (exclude). This selection assures that the report will ignore orders that are “technically completed.” This screen shows the list restricted to orders that do not have the DLV status. The actual start date for these orders is more than 60 days ago.

This screen shows the list restricted to orders that do not have the DLV status. The actual start date for these orders is more than 60 days ago.